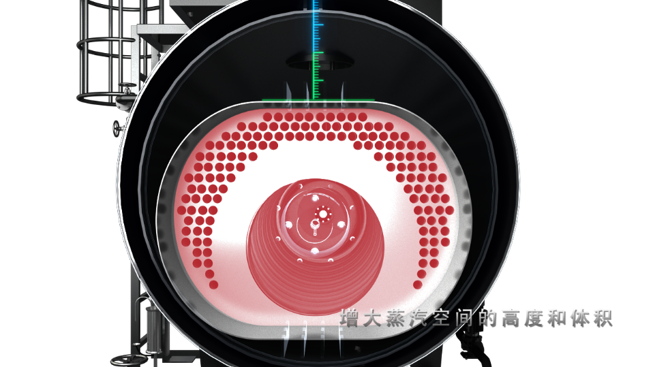

1.Oval Shape Reverse Chamber

Oval shape reverse chamber allows a larger drum size, which increases the steam quality, dryness up to 99.83%.

2.Air-preheater

Air-preheater increases heat recovery.

It can start to heat up the combustion air fast at low temperature, preventing the condensation corrosion to the burner and boiler.

Finned tubes in silicon magnesium aluminum alloy, with good heat exchange and anti-corrosion ability;

Counter-flow heat exchange, efficient heat transfer to heat up the air and accelerate the combustion, which efficiency can be up to 100%

Boiler efficiency increases up to 3%.

3.Air-cool Smoke Box

Reduce heat loss, and surface temperature, improve thermal efficiency;

Combustion air through the smoke box to cool down the surface heat and recover back to furnace, thereby reducing the heat loss, greatly reducing the surface temperature and improving the thermal efficiency.

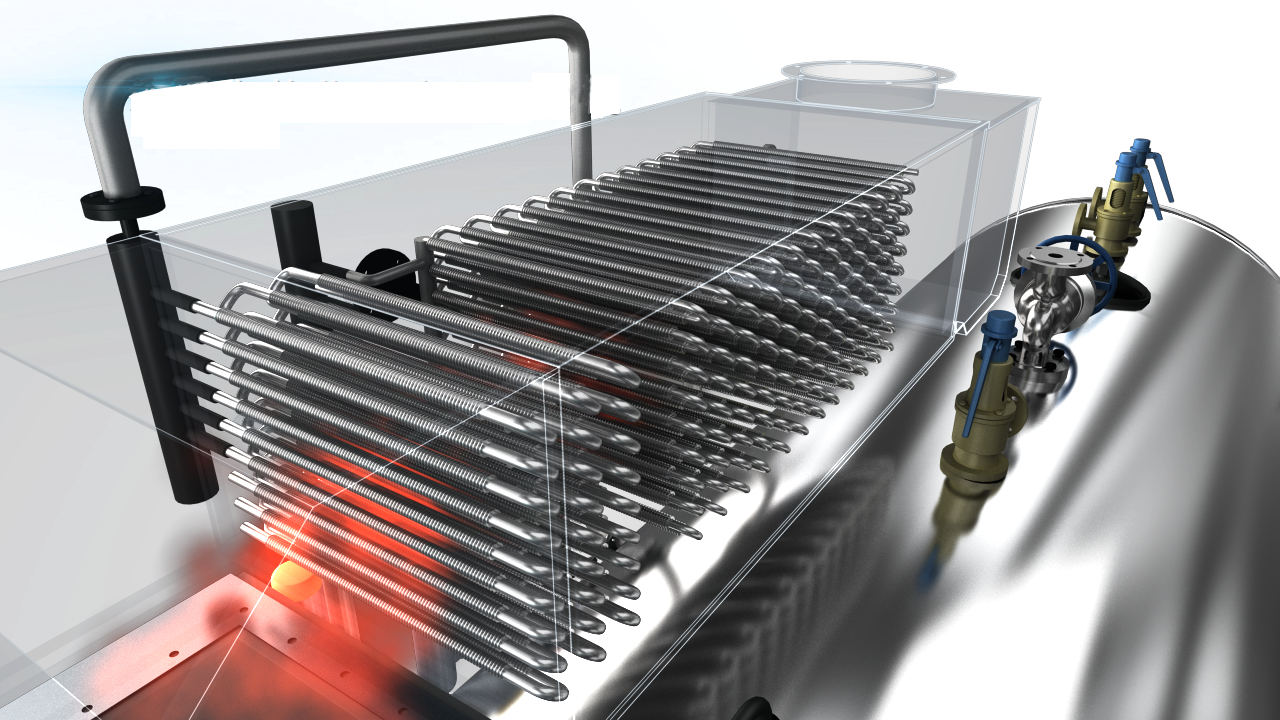

4.Integrated Economizer and Condenser

ND steel + silicon-magnesium-aluminum alloy winding composite finned tube with better heat transfer

Material: ND steel + silicon-magnesium-aluminum alloy winding composite finned tube;

Features: better heat transfer performance, stronger acid corrosion resistance:

Effect: efficient operation, effectively improving the thermal efficiency of the boiler;

Principle: The sensible heat and latent heat of the flue gas are recovered to the limit, with exhaust gas temperature reduced; the thermal efficiency of the boiler is increased by more than 8% and the NOX emission is reduced.

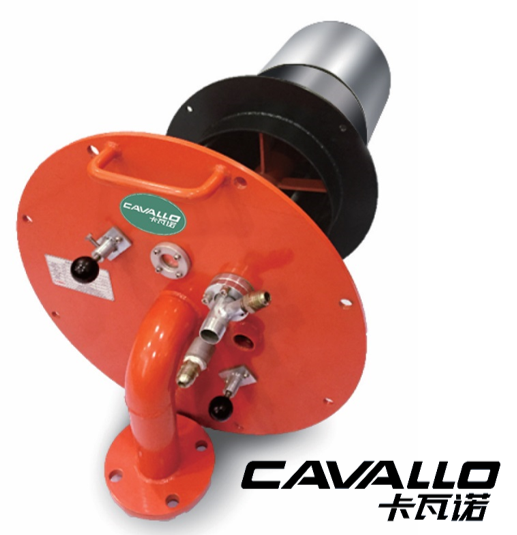

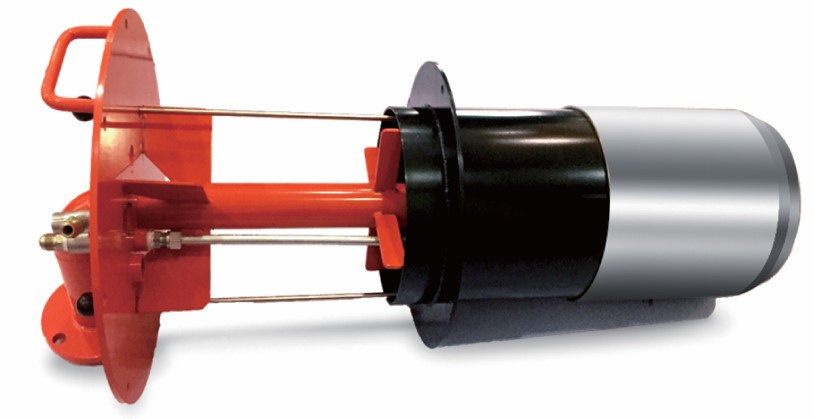

5.FGR+ Ultra-low NOx Dual-bloc Burner from Cavallo

FGR technique to reduce ultra-low NOx emission

Target: NOX≤30mg/m3

Method: FGR + low NOx burner to achieve 30mg/m3 NOx emission

Measures: Recirculate flue gas, to reduce the combustion temperature and oxygen content, and suppressing the generation of NOx

Technology: flue gas recirculation technology

Features: built-in; save installation space; ensure the safety of operator